By Rjay Zuriaga Castor

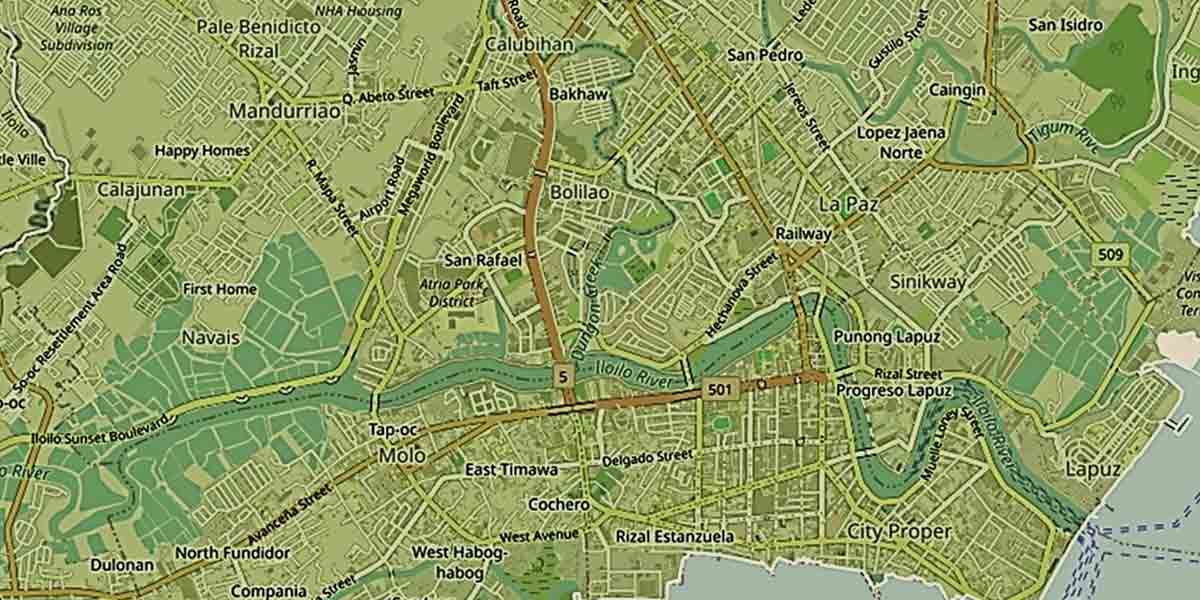

The Department of Public Works and Highways Western Visayas (DPWH-6) will introduce geofoam technology in the second phase of repairs for the sinking Ungka Flyover in Pavia, Iloilo.

DPWH-6 Director Sanny Boy Oropel explained to the Daily Guardian that geofoam will be used to correct the vertical alignment of flyover sections that have experienced settlement.

“The purpose of the geofoam is to level up and achieve the exact design of the flyover that has experienced settlement,” he said.

Geofoam, a rigid, cellular foam polymeric material, will be integral to the superstructure repairs.

The project includes a budget allocation of PHP 32.8 million for 1,645 geofoam blocks, part of the PHP 192 million budget for the second phase of repairs being undertaken by the International Builders Corporation.

The DPWH defines geofoam as a block or planar rigid cellular foam polymeric material used in geotechnical engineering applications.

Oropel addressed public concerns, assuring that there would be no structural issues despite this being DPWH-6’s first use of geofoam.

“This is the first time for Region 6, but geofoam has existed for 20 years. It is not a new material or technology. Geofoam is used in flyovers, embankments, and skyway approaches,” he said.

Infrastructure projects in the country using geofoam include Metro Manila Skyway Stage 3, the NLEX Connector Road linking the North Luzon Expressway and South Luzon Expressway, and the C5 South Link Expressway, where it was used to minimize settlement issues over soft soil conditions.

Oropel emphasized that geofoam’s lightweight nature could expedite the alignment correction process for the Ungka Flyover and support the agency’s goal of opening the flyover to full capacity by December 25.

“The required testing has already been done to meet specific specifications for the geofoam,” he added.

The decision to use geofoam followed research by the DPWH Bureau of Research and Standards, which found the material to be “very durable, lightweight, cost-efficient, and time-saving.”

In 2017, the DPWH issued an order detailing the standard specifications for geofoam as an alternative embankment material.

According to the department order, the geofoam to be used should be expanded polystyrene, a type of foamed plastic formed by expanding polystyrene resin beads through a molding process.

After the vertical alignment is corrected, the DPWH will add a load distribution slab layer, made of reinforced concrete, between the geofoam blocks and the overlying pavement system.

A third-party geotechnical study revealed that three of the flyover’s 16 piers sank more than one foot between May 2022 and April 2023. The study showed Pier 5 sank by 22.9 inches, Pier 6 by 19.21 inches, and Pier 4 by 16 inches.

Due to the sinking, the flyover was closed to traffic for over a year until it was reopened for inner lane use in September 2023.

Repairs began earlier this year, with the first phase nearing completion and the second phase starting in October.